One of the most common questions that we get asked, is ‘How do I make 300+ Bhp?’ and although this is not a ‘how to guide’, this project will certainly whet the appetite of those wanting to stand out in the MINI community. Our main focus here at Lohen is performance, we are continually looking to create MINIs that inspire and wow the MINI community, so when a project like this one comes knocking it sets our tuning tails wagging.

While we love every job that comes through the doors here at Lohen, we get particularly excited when we get a job that lasts a few months, so when this R56 Cooper S showed up for a serious performance overhaul we wanted to produce something any MINI tuner could be proud of.

Like always, this customer’s first visit to Lohen began with some simple modifications to improve their MINI. Beginning with our Simple Decoke service which helps to get rid of the carbon build up around the valves and intake ports, he then went on to get an AEM Strut Brace, some Lower Engine Mount Bushes, a Coolant and Boost Hose Kit and a Stage 2 Re-map. With the work complete and with a few extra miles put on the clock, it was clear that this customer had the bug for tuning as he soon booked his MINI in for more.

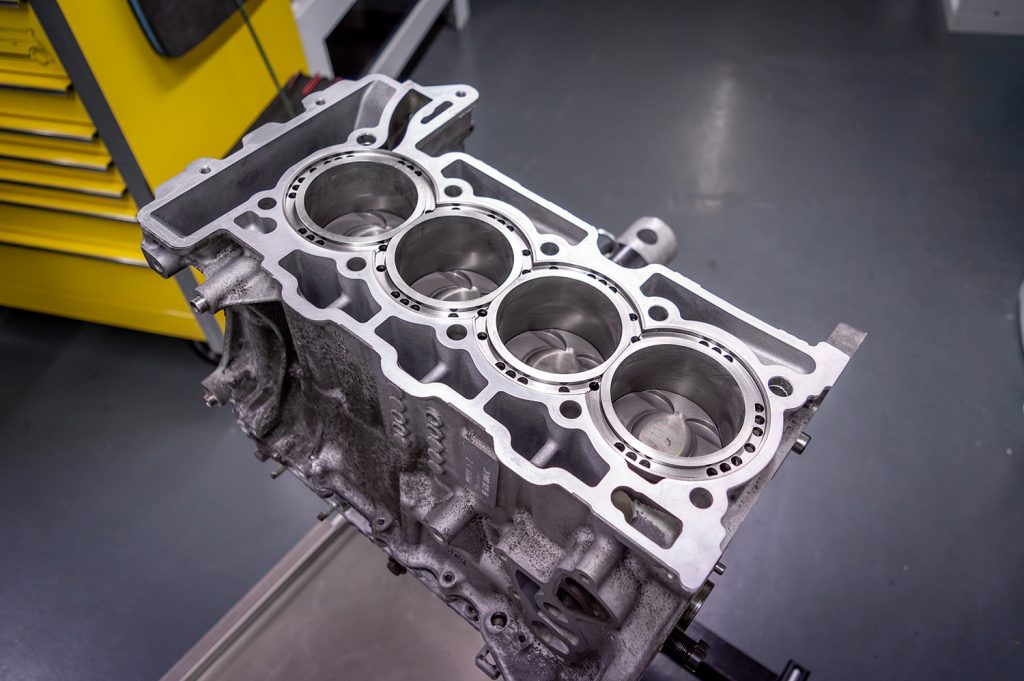

Returning with the goal of achieving 300+ bhp, this customer opted for a Config 5 Crate Engine Build. This crate engine configuration is recommended to those MINI owners running high-performance Stage 3+ N14 engines that require internals that can withstand much more abuse than what the standard engine was made for. Having opted for the Config 5 engine this customer went with the Closed Deck option by adding a set of Darton Sleeves to the block.

Lohen Configuration 5 Crate Engine Build

- Supertech N14 Pistons 9.5:1 Compression Ratio

- Supertech Connecting Rods with ARP Bolts

- ARP Head Stud and Main Bolt Kit

- Mahle Big End Bearing

- Mahle Main End Bearing

- Supertech Intake Valves

- Supertech Beehive Springs

- Supertech Titanium Valve Retainers

- Schrick Cams

Why choose a Closed Deck Engine?

When turbo-charged engines like the ones in the R56 Cooper S or JCW MINI are tuned the engine output is increased, this increase in engine output causes a build-up of cylinder pressure, which can cause cylinder cracks, however, this can also occur on standard cars. One solution to prevent the cylinders from cracking is to reinforce the block (Closed Deck), this ensures that cylinders are completely supported especially in areas that are most affected by this increased cylinder pressure. Lohen’s Closed Deck engine option comes with the use of Darton Sleeves, their unique design creates a solid deck of flanges which are held in tension and help reinforce the upper deck area. The use of sleeves gives a greater area of support than a deck guard and Darton’s Modular Integrated Deck means that they can be individually replaced should anything happen, thus making life a whole lot easier and cheaper than buying a new engine to the same spec.

There are several steps that need to be taken to successfully install a set of Darton Sleeves, firstly the engine block has to be stripped and inspected before it is machined. Secondly, a significant amount of the existing block is machined to facilitate the new sleeves. Once this step is completed the sleeves are then ready to be dropped in, its recommended that they are dropped into the block two at a time to assure that the sleeve flats are perfectly aligned. The sleeves are fitted by heating the block in a hot wash solution and chilling the sleeves, the sleeves are then fitted into the block and held in position by means of a deck support until it all returns to room temperature. Opting for a Closed Deck Block engine meant that this customers engine will be able to withstand prolonged periods of high heat and the increased cylinder pressures that are associated with heavily tuned engines like this one. The use of Darton Sleeves means that his engine block has the support it requires, whilst offering superior oil and compression control, improved cooling and an increase in the potential hp output.

Improved Braking Performance

The braking performance of the stock Gen 2 MINI can quite often leave owners feeling near the limit especially when driving hard and this becomes increasingly more apparent when a cars engine performance is increased. This customer opted to install one of our new Tarox SuperSport 10 Pot 2 Piece Big Brake Kits to his MINI. Tarox’s unique disc finish provides an ultra-stable braking surface and unparalleled heat resistance that together offer a huge amount of stopping power and provide the best drive possible for the MINI. The extra large 340 mm brake disc with a thickness of 26mm provided in this Big Brake Kit from Tarox means that these brakes can withstand extremely high working temperature, they take longer to heat up and they can disperse heat a lot faster making them a great option for those cars pushing higher power.

Monitoring Performance and Styling

While his main focus was on performance, this customer also decided to make his MINI more visually appealing too. To accompany and show off his new Big Brake Kit, he asked us to add a set of Sparco Assetto Gara Matt Black Wheels and some Michelin Pilot Sport Tyres which are performance focused. The classic 10 spoke wheel design from Sparco paired with the Big Brake Kit from Tarox certainly help to make this MINI stand out from the crowd. Deciding on some interior modifications too, he also chose to get some Defi Gauges (Oil and Water Temperature Gauges) which are securely displayed using a CravenSpeed FlexPpod Mount. Both these gauges are important for those MINI owners to monitor if they have increased performance in their MINI and if they are using their car on the track. While the config 5 engine was being built, the car was stripped so a GP2 rear interior could be installed, which helps to add to the sporty look this customer was after.

The Finishing Touches

Once all the modifications were made and the engine was built, it was then reinstalled and ran up. The running in the process begins with running in oil being added, it is then driven on the dyno for approximately 70 miles at low rpm, this is done at low revs initially as this allows the engine parts to bed-in. After this is complete the running in oil is emptied and the engine is flushed where the oil is replaced with a Millers 10w50 Nano Drive Fully Synthetic Performance Oil and a K & N oil Filter is fitted and a further running in period is completed. Once all this had been done, this car then had a Lohen Customer ECU tune added before it was put back on the dyno for some power runs. On the dyno, this car made 305.1 bhp and 408.4 N, of Torque.

The range of performance parts chosen by the customer for this MINI overhaul are some of the best modifications available on the market and I’m sure you’ll agree that both the interior and exterior modifications installed help this MINI to stand out from the crowd. Thanks for reading this, we hope you love this project as much as we do. If you are interested in taking your MINI to the next level with a complete performance makeover then please contact our sales team on [email protected] you can call them on 01785 859999. You can keep up to date with all the jobs that take place here at Lohen by following us on social media.