You will find bushes on your MINI anywhere there’s a joint in the suspension, they work like knees and elbows do in the human body; absorbing shocks from bumps and divots in the road and preventing metal to metal contact. Automotive bushes are designed to cushion the movement between two solid parts, helping to absorb shocks and vibrations. They have a very important role to play in making sure that your MINI drives smoothly, they are acting as pivot pieces in systems such as the suspension and they link components of the car together. When they wear these components develop ‘play’ and do not work in their optimal plain or direction. Automotive suspension bushes also help to dampen the impact of an uneven road surface on the suspension.

There are several types of automotive bushes, but they all work in the same way, engine bushes help to reduce vibrations and thus wear on other parts of the vehicle such as exhaust pipes, while suspension bushes are fitted to cars at all points where the vehicle’s chassis is joined to a moving suspension component. They are fitted to provide a noise and vibration barrier between the road and you.

The standard MINI bushes are made of rubber, this is the material that the majority of OEM automotive manufactures use as rubber bushes are cheap to manufacture and easy to work with.

Conventional rubber bushes deteriorate with age and become softer and more pliable, resisting the forces placed on them less and less and therefore allowing more movement of the suspension components, which causes increased tyre wear, braking instability, and poor handling.

Whilst they are good for everyday driving, under load, rubber bushes tend to stretch, flex and compress, which can transfer to your cars steering, this can cause issues with traction and can create increased oversteer or understeer.

When do my bushes need replacing?

If your MINI is still running the OEM rubber bushes then they are going to deteriorate over time, they will become brittle, crack or even break, at this point a replacement needs to be fitted.

Some symptoms of worn bushes normally include an uncomfortable ride and unstable feel to the car, especially when braking, accelerating and going through corners. Other subtle clues include uneven tyre wear, wayward handling and increased road noise. Identifying these issues can be more difficult on a car that is driven every day as the wear to the bushes tends to occur gradually, the majority of bush issues are identified during an MOT test.

What’s available?

Polyurethane Bushes

Polyurethane (PU) was adopted during World War 2 to replace rubber in many applications due to its superior performance and the scarcity of rubber raw materials during this time. Polyurethane is a hard material that gives excess NVH (Noise, Vibration, Harshness), however, this is not the case in all applications.

According to Harkness Industries (2019), Polyurethane has a higher abrasion, cut and tear resistance than its rubber counterpart, in most cases, it lasts longer and stands up to compression and load better. It is resistant to heat, road chemicals, other oils and UV rays. It is weatherproof and wear-resistant and doesn’t warp or distort like rubber.

Powerflex Bushes

One of the biggest manufactures and our recommended manufacturer of suspension bushes is the brand Powerflex.

Powerflex bushes are made from a technologically advanced PU plastic compound, which doesn’t age or perish and has a long working life (up to 3-4 times longer than the conventional rubber bushes). Powerflex have been engineering a Polyurethane compound that makes their bushes 25-30% stiffer than the rubber OEM counterparts but with the same noise absorbing properties. Being a stiffer material means that the Powerflex bushes can withstand significantly more cycles of repeated stress than their rubber counterparts. This stiffer material is also more likely to last the lifespan of the vehicle.

Powerflex bushes improve your cars road-handling and chassis performance by controlling the amount of unwanted flex in the suspension. It means that your tyres have greater contact with the road at all times, therefore improving safety and performance.

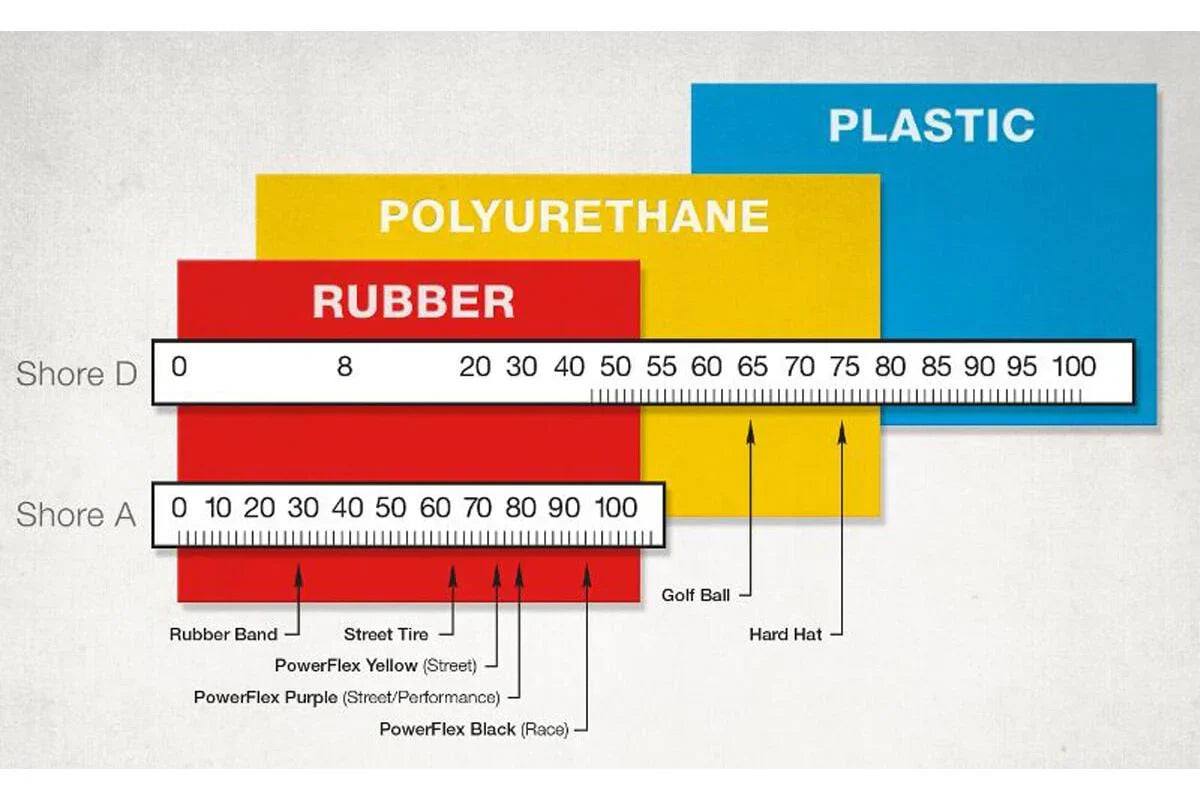

Durometer is a piece of equipment thats used to measure something, it is the International standard for measuring the hardness of rubber, plastic and nonmetallic metals. Different material types are tested and measured in different scales depending on their properties. The Shore A scale measures the hardness of flexible mould rubbers that range in hardness, whereas the Shore D scale measures the hardness of hard rubbers, semi-rigid plastics and hard plastics. The diagram above (Diagram 1) shows where Powerflex bushes are rated on the Shore A scale, the higher the shore rating, the firmer/harder the bush. Powerflex colour code their bushes based on their hardness, table 1 below lists these common colours within the Powerflex brand and their uses.

|

Bush Colour |

Durometer Rating |

Use |

Stiffness |

|

Red |

65A |

Used for universal exhaust mounts and diesel engine mounts. |

Similar to OEM but are several times stronger due to the use of the polyurethane material |

|

Yellow |

70A |

Mainly used for engine mounts and subframe mounts where the bush needs a lot of movement and absorption. |

Approximately 25% stiffer than stock bushes. |

|

Purple |

80A |

Powerflex’s most common material. It is used in most areas of the suspension and provides the right mix between performance and compliance. |

Approximately 30% stiffer than stock bushes. |

|

Black |

95A |

Powerflex’s hardest material. This is used for the Black Series range or normal vehicles where the vehicle. Suspension demands require us to use this hardness of material i.e. in areas of high load. |

Approximately 80% stiffer than stock bushes. |

Purple Series (Road Series)

The Powerflex Road Series helps to enhance your MINI’s road grip and chassis performance by minimising the flex in your suspension.

The Powerflex Road Series bushes are geared towards those cars used for everyday driving purposes, they are also suitable for those MINI owners wanting to improve their MINI’s handling and chassis performance without drastically compromising on comfort. Powerflex tests the original bushes to see what is required in terms of movement and strength and from there they choose which of the 4 materials listed in the table above would be best suited to each suspension component.

Using the Powerflex Road series bushes means that your tyres will have greater contact with the road at all times, improving not only performance but safety too. The Powerflex Road series bushes offer prolonged tyre life, improved performance, increased safety and increased cost-effectiveness making them the perfect option for those that use their MINI on the road on a daily basis.

Black Series

The Powerflex Black Series bushes are manufactured using Powerflex’s hardest compound in order to provide the maximum control over the chassis geometry by minimising points of flex. The Black Series compound has a Shore value of 95A and is up to 80% more resistant to load than the standard rubber bushes.

If your requirements are purely for the ultimate in handling and chassis performance and you don’t care about comfort then the Black Series bushes are perfect as they offer the most precise and accurate alignment for your MINIs chassis. However, it is important to note that it all comes down to application and personal preference, using the Black Series Bushes throughout the vehicle can make it feel too stiff, so in some cases, a mix of the Black Series and the Road Series bushes might be better.

All Powerflex Bushes are carefully designed and tested to ensure they are a direct replacement or work seamlessly in conjunction with the existing bushes. Powerflex makes sure they chose the right polyurethane hardness for your applications. Replacing only the weak links (or the necessities) in your MINIs suspension is a great way to tighten your handling without putting too much stress on your budget.

Best application for my MINI?

Fast Road

Some of the common bush upgrades made to fast road MINI’s include front wishbone rear bushes, anti-roll bar bushes, rear trailing arm bushes and engine mount bushes, which if you get fitted altogether takes around 6 hours.

Front wishbone rear bushes help to reduce the amount of free-play in the wheel mountings which reduces tyre wear and makes the handling more predictable. Anti-roll bar bushes reduce the flex and warping more than the standard rubber bushes, they ensure that the anti-roll bar is working at its optimum. Trailing arm bushes cushion the movement of the suspension while holding the wheel on the correct axis. Engine mount bushes control the amount of noise, vibration and harshness while still offering superior control over engine movement, which helps to improve power delivery and traction allowing for a more direct drive.

The benefits of these upgrades will create a slightly firmer ride with less movement in the suspension components and therefore keeping the suspension geometry closer to the specification.

Track

Common bush upgrades for those MINIs used out on the track are similar to the upgrades mentioned above for fast road applications, however, they may also benefit from the use of rear shock absorber mounts, rear control arm bushes and steering rack bushes.

The rear control arm bushes allow for more stable geometry, which means that castor and camber can be more accurate. Rear shock absorber mounts improve the performance and safety of your MINI and help to prolong tyre wear, steering rack bushes reduce the amount of vibration through the steering assembly whilst helping to keep other components working at their best.

While Powerflex recommends their Black Series for those cars used on the track as they are substantially stiffer than the stock bushes and they have little to no compliance. However, it is important to note that if the car is used on the road, then you may want to compromise and use a mixture of the Road and Black series to improve your ride comfort.

While Powerflex recommends their Black Series for those cars used on the track as they are substantially stiffer than the stock bushes and they have little to no compliance. However, it is important to note that if the car is used on the road, then you may want to compromise and use a mixture of the Purple and Black series bushes to improve your ride comfort.

Race

If you are racing your MINI then we recommend that you do the same bush upgrades as you would if you were tracking your car. As racing for most people is an application where additional vibration is not a problem, using Powerflex’s Black Series bushes wherever possible will give you the most precise and accurate alignment for your MINIs chassis.

Our past experience has shown that the black series bushes are a better choice if you are using slick tyres, so we would, therefore, recommend using these bushes wherever possible.

What are the common bush upgrades and when to do them?

One of the most common bush upgrades that we do to MINI’s in our workshop is front wishbone rear bushes, as these are the bushes most likely to fail. You are likely to notice the biggest difference when upgrading these bushes as they affect the MINIs braking, steering and handling.

We recommend that if you are going to fit a set of Front Wishbone Rear bushes (Or any suspension bush upgrades) that you do it while your MINI’s subframe is dropped for example, alongside a clutch or differential fitting. That way the subframe doesn’t have to be dropped again, this is done to save on labour costs, fitting the bushes on their own takes three hours.

If you are planning on booking your MINI into our workshop for some front wishbone rear bushes, then we will need your car for approximately 3 hours or an additional 1 hour if you are fitting a clutch, our labour costs are £72 per hour. If you are fitting other bushes too then please be aware that additional time will be required to fit these.

Other common bush upgrades include engine mount bushes and anti-roll bar bushes. While engine mount bushes are a more popular upgrade for the Generation 1 MINI we do fit them to the Generation 2 MINIs too as they are a common point of failure in both cars. The biggest difference that you will notice when upgrading these bushes is better gear changes and less engine movement. It is important to note though that you may experience more vibration if you fit these bushes. Fitting engine mount bushes doesn’t take very long especially if you are fitting them while doing another job that requires the subframe to be removed.

Anti-roll bar bushes are also a common bush upgrade for MINIs, these help to reduce body roll by stiffening your MINIs chassis. We will need approximately 30 mins to fit a set of anti-roll bar bushes to your MINI, but if you fit them with a set of front wishbone rear bushes we require less time as they both require the subframe to be off the car.

We hope you find this blog useful, if you want more information about what Powerflex Bushes can do for tour MINI then please don’t hesitate to contact us. To book your MINI in then contact our sales one sales@lohen.co.uk or 01785 859999.